In the contemporary industrial landscape, it is imperative to transform current production lines, both manual and automated, into highly efficient and versatile lines. However, the pursuit of "producing more and diverse with less" underscores the evolution toward this goal. In addition, this pursuit is accompanied by a series of challenges that need to be taken into account. For instance, the proliferation of product variants places a challenge on the development of reconfigurable and flexible handling tools and strategies, capable of seamlessly accommodating a wide array of product types.

Due to all of this, SMARTHANDLE, a research and innovation action project, will focus, among other topics, on techniques to improve the grasping and manipulation of both known and unknown objects, the latter considered as slightly different variants of the former with no full 3D information available before the manipulation starts. Grasping has been a long-standing and fundamental research topic in robotic manipulation, as it is a crucial step towards the achievement of more complex manipulation tasks such as (dis)assembly, packaging, and sorting of industrial workpieces. Specifically, grasping is the process by which a robotic system or device picks an object by using a specialized robotic end-effector, typically referred to as the gripper. The goal of grasping is to securely and stably hold an object, often in preparation for further manipulation, which includes the object’s transport and placement. In the context of the SMARTHANDLE project, the objects to be grasped and manipulated are workpieces belonging to three different, but representative, use-cases, namely aluminum profiles, contact lenses, and end-of-life electric vehicle batteries components.

As stated before, one of the main challenges in grasping refers to the inherent complexity and variability of the objects to be grasped. In addition, the presence of noise and uncertainties in the sensor data, the need for adaptability and robustness to changing environments and tasks, and the trade-off between speed, accuracy, and safety in the grasping process also represent important challenges to be addressed. To tackle these challenges, classical grasping techniques such as analytical and heuristics methods are commonly used. These approaches involve analyzing the object's geometry and physical properties, as well as the capabilities and constraints of the robotic manipulator used for grasping. However, both analytical and heuristics methods have their strengths and weaknesses in grasping tasks. Analytical methods can provide optimal grasp solutions but may be computationally intensive and may not always account for real-world uncertainties. Heuristic methods, on the other hand, can be more flexible and adaptable but may not guarantee an optimal grasp. Therefore, classical grasping methods often struggle to cope with the aforementioned challenges, as they require precise and complete knowledge of the object geometry, friction, and dynamics, which is often hard to obtain in practice.

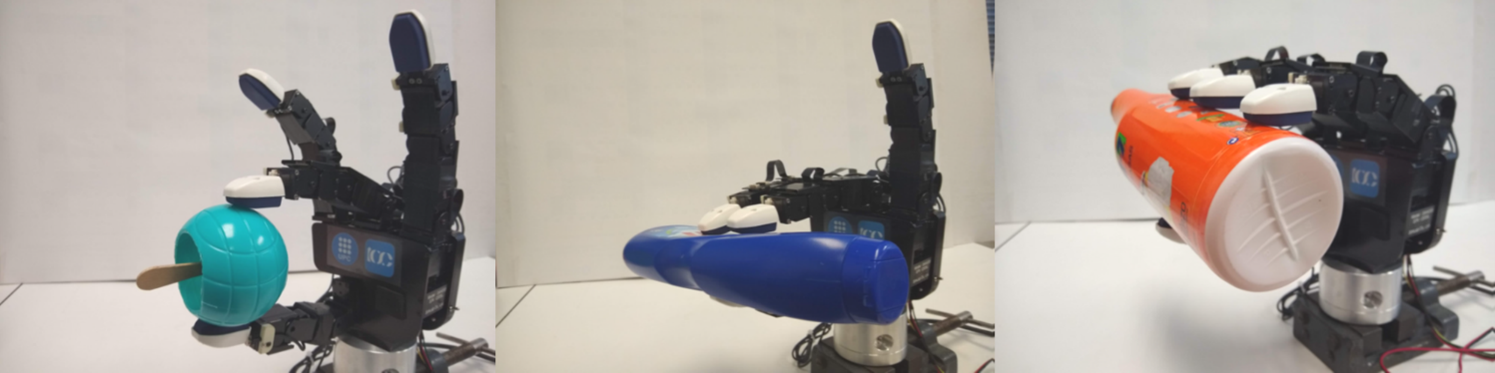

As a result, in recent years, there has been a growing interest in data-driven grasping strategies that rely on artificial intelligence techniques to learn grasping strategies directly from sensory data, without the need for explicit models or assumptions about the objects or the environment. However, data-driven strategies still have several limitations that affect their adoption for manipulation tasks in industrial contexts, such as their dependence on the gripper used, their low performance for kinematically complex grippers (e.g., centric grippers with three or four fingers), and the lack of standard manipulation-related grasping quality measures that allow the learning of specific manipulation-oriented grasping strategies. These are the research topics regarding grasping that will be investigated within the SMARTHANDLE project, and that Universitat Politècnica de Catalunya – BarcelonaTech (UPC) will be in charge of. In particular, the main objective consists of using the perception data from the known and unknown workpieces to extend current deep neural networks architectures to tackle not only the grasping problem but also to develop a grasping strategy oriented to an optimal post-grasping manipulation (e.g., keeping the orientation of the contact lenses during their manipulation, being able to grasp removed screws or cables during the disassembling of the EV batteries).

In conclusion, the efforts within the SMARTHANDLE project regarding the grasping and manipulation of the workpieces belonging to the three representative use cases consist of the use of artificial intelligence, in particular, deep learning, to develop models that can create smart and robust manipulation-oriented grasping strategies capable of handling a wide set of product types whose models may not be necessarily known.

The author of this piece is UPC.