The SMARTHANDLE project focuses on developing advanced handling systems for automated manufacturing processes. Within the Menicon use case, Menicon works on automating the production of made-to-order contact lenses, in close collaboration with their development partners. The goal is to develop an Automated Lens Production line. The development partners, Demcon industrial systems and STT Products, closely work together. Each of the partners brings in specific knowledge in hardware, software, and specific manufacturing needs to innovate and improve automated handling technologies.

Recap of the progress and current prototype milestone

The Menicon use case continues to push the boundaries of automating smart handling. In our first blog, we introduced the challenges of automating the handling of delicate, made-to-order contact lenses and how we proved different concepts in solving these challenges. A year later, we’re proud to share the progress on the most recent prototypes, turning ambitious concepts into real, testable hardware.

To review some of these challenges: producing contact lenses at scale and on-demand requires precise and flexible handling of multiple materials: raw material, semi-finished parts, tools, and the fragile lenses themselves. A standard industrial gripper couldn’t meet the requirements in terms of space constraints, precision, and grip feedback. So, custom solutions were designed in the early stages of the use case.

Since the first prototype stage in which the concepts where proven the team has now finalised most prototypes and made major improvements along the way.

Prototype 1: Gripper

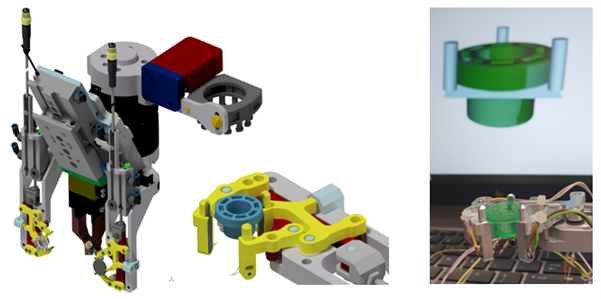

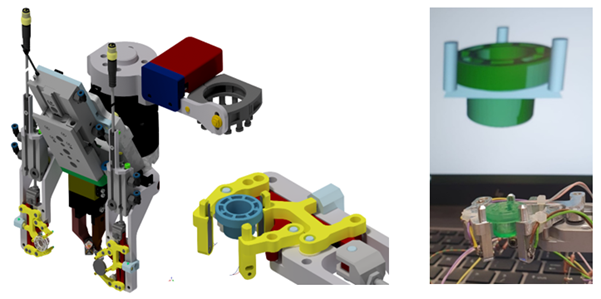

The gripper for the handling robot was extensively discussed in the first blog and has undergone several improvements. This gripper developed for the Lens Lathing Cell now supports:

- Loading/unloading of base material and semi-finished lenses

- Automatic tool exchange for the dual lathes (inner and outer)

- A robust docking mechanism that ensures sub-millimeter repeatability

Improvements were also made in the design of the gripper: simplified, more robust, and easier to manufacture, without sacrificing functionality.

Tactile feedback

Perhaps the most innovative upgrade in the gripper prototype is tactility of the gripper fingers. The gripper is equipped with strain gauges sensors to detect object presence and grip quality. This feedback is visualised through an intelligent interface, showing whether the gripper is empty, holding a correctly placed item or detecting a misalignment.

This prototype will undergo real-world testing in a simulated environment before integration in production.

Prototype 2: Flexible transport system

Efficient transport is just as crucial as smart gripping. It extends to how materials and lenses move between process steps. That’s why the SMARTHANDLE project includes two coordinated transport systems:

- T1: for material and semi-finished workpieces, using RFID-tagged carriers with flexible routing. These carriers hold up to three components, typically a disc, a mounting base, and a semi-finished product, and are compatible with Flexlink conveyors. Every production cell along the line shares a standardised interface for these carriers, enabling seamless handover of materials and simplifying integration.

- T2: for individual lenses, currently supported via containers in manual processes. For now, the team uses lens containers as a practical interim solution, mirroring the current manual process.

Together, these systems support flexible, traceable movement of products throughout the pilot line, critical for achieving full automation in a made-to-order context.

Uniqueness of the prototypes

These prototypes are highly customised, yet their functionalities are suitable for other handling applications as well. The high level of customisation was needed since standard parts wouldn’t fit within the spatial of functional needs for handling in the Automated Lens Production line.

The prototypes have been built with testing in mind from day one. Various iterations on functions and the prototypes have taken place in a controlled environment to de-risk final deployment.

Modularity and scalability play an important role in the development of these prototypes. The flexible architecture supports future changes in product or process.

Next steps

The focus now shifts to extensive real-world testing, followed by integration into the ALP pilot production environment at Menicon. This ensures that before full deployment:

- The tactile systems are validated under realistic conditions

- Cycle times and handling accuracy meet production standards

- System robustness matches the expectations for continuous operation

The SMARTHANDLE project has reached a major milestone with the delivery of its final hardware prototypes. With rigorous testing ahead, the project stays on track to transform flexible handling into a practical, scalable solution.