SMARTHANDLE participated in the "The Manufacturing Partnership Day" 2023 event, organized by EFFRA

📣 On September 26th #SMARTHANDLE participated in the "The Manufacturing Partnership Day" 2023 event, organized by EFFRA.

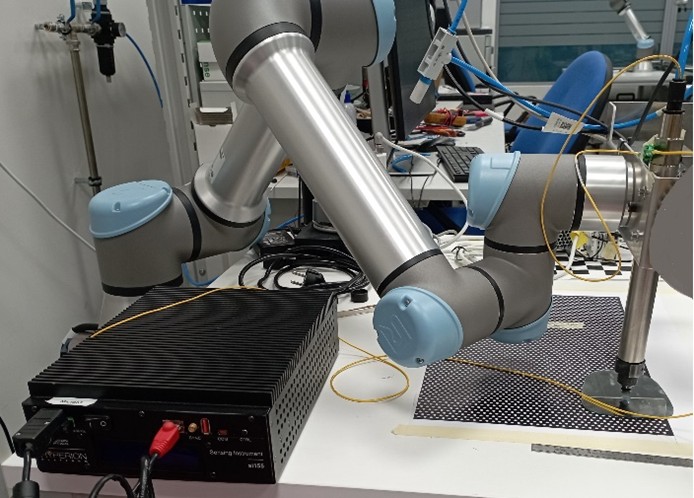

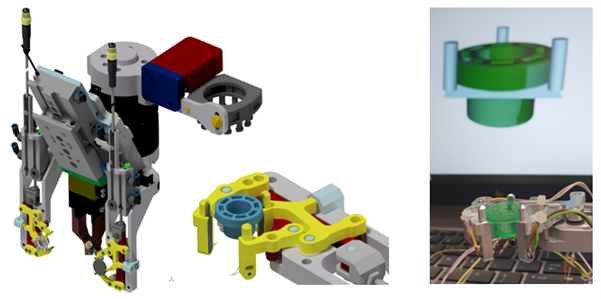

Tactile monitoring system based in a Fabry Perot sensor to detect small changes in pressure applied to vacuum a contact lens using a suction cup

A new Fabry-Perot-based fiber optic sensor enables precise, real-time control of vacuum-assisted robotic grasping for delicate, deformable objects like contact lenses, ensuring safe, reliable, and damage-free handling in automated manufacturing processes.

Advancing packaging at ALUMIL: ALUMIL's progress with the SMARTHANDLE Project

As part of the SMARTHANDLE project, ALUMIL is developing a dual-arm robotic packaging solution for handling large, multi-variant aluminium profiles. In collaboration with the University of Patras, this pilot aims to boost packaging efficiency, reduce errors, and improve worker safety, while paving the way for smarter, more flexible manufacturing.

Motion planning with geometric constraints

UPC has developed a motion planning framework within SMARTHANDLE to enable flexible, constraint-based robot movements for industrial tasks. Built on OMPL and integrated into the Kautham platform, it allows easy configuration, 3D visualization, and real-world testing, enhancing robot adaptability in scenarios like assembly and manipulation.

From proof-of-concept to full prototype: Smart handling in automated manufacturing

The SMARTHANDLE project has delivered custom prototypes for automating Menicon’s contact lens production, including a smart gripper with tactile feedback and a flexible transport system. Developed with Demcon and STT Products, these solutions are now entering real-world testing ahead of integration into the pilot production line.

Subscribe to Technology