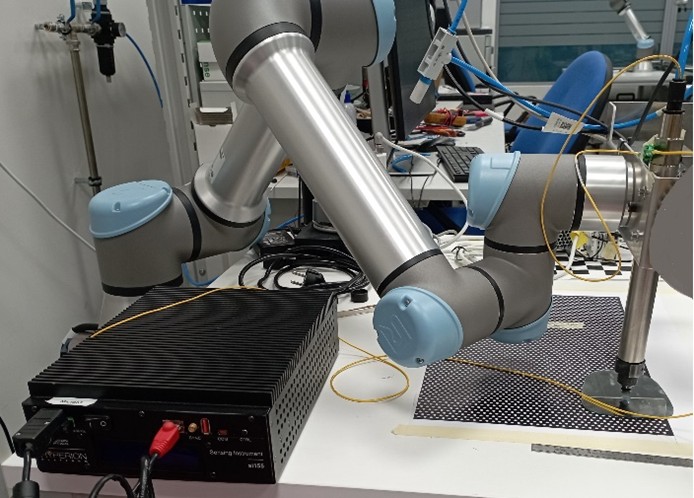

Tactile monitoring system based in a Fabry Perot sensor to detect small changes in pressure applied to vacuum a contact

A new Fabry-Perot-based fiber optic sensor enables precise, real-time control of vacuum-assisted robotic grasping for delicate, deformable objects like contact lenses, ensuring safe, reliable, and damage-free handling in automated manufacturing processes.

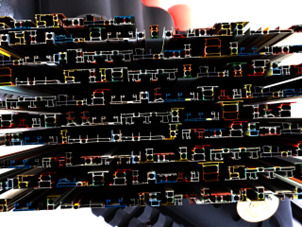

Advancing packaging at ALUMIL: ALUMIL's progress with the SMARTHANDLE Project

As part of the SMARTHANDLE project, ALUMIL is developing a dual-arm robotic packaging solution for handling large, multi-variant aluminium profiles. In collaboration with the University of Patras, this pilot aims to boost packaging efficiency, reduce errors, and improve worker safety, while paving the way for smarter, more flexible manufacturing.

Motion planning with geometric constraints

UPC has developed a motion planning framework within SMARTHANDLE to enable flexible, constraint-based robot movements for industrial tasks. Built on OMPL and integrated into the Kautham platform, it allows easy configuration, 3D visualization, and real-world testing, enhancing robot adaptability in scenarios like assembly and manipulation.

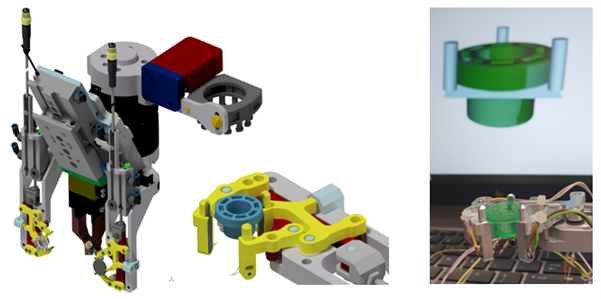

From proof-of-concept to full prototype: Smart handling in automated manufacturing

The SMARTHANDLE project has delivered custom prototypes for automating Menicon’s contact lens production, including a smart gripper with tactile feedback and a flexible transport system. Developed with Demcon and STT Products, these solutions are now entering real-world testing ahead of integration into the pilot production line.

Dual-arm robot system for aluminium profile handling

KUKA is contributing to the SMARTHANDLE project by developing a dual-arm robotic system for automated aluminium profile handling. The setup features advanced 6D pose estimation, AI-driven grasp selection, and collision-free motion planning, supported by impedance control for safe operation. Initial tests were successful, and future improvements will focus on enhancing pose accuracy, integrating smarter grasp planning, and adopting adaptive, object-based path execution.

Hand gesture recognition as a quick interface to command robot behaviour

The SMARTHANDLE project is developing a hand gesture recognition system that uses machine learning and real-time visual processing to control robots intuitively through natural movements. Currently being developed at AIMEN for use with different robot models, the system is being refined for greater accuracy and user-friendliness by training on diverse hand data and simplifying gesture execution.

AI-based 6D Pose Estimation Leveraging the Power of Synthetic Data

AI-driven 6D pose estimation is transforming industrial automation by enhancing robotic vision and efficiency. Synthetic data provides a scalable solution for training deep learning models, addressing challenges in real-world data collection. A case study in the metal industry showcases how Roboception leverages Blender-generated synthetic datasets to improve object detection and pose estimation, ensuring adaptability in dynamic manufacturing environments.

Robot learns from demonstration in car battery dismantling

Efficient and safe disassembly of electric vehicle batteries is crucial for meeting the growing demand for sustainable transportation. By integrating automation, machine learning, and teleoperation, the process can be optimized to ensure worker safety, precision, and adaptability to diverse battery designs. These innovations not only reduce risks and environmental impact but also accelerate recycling efforts, paving the way for a more sustainable and scalable electric vehicle ecosystem.

Battery Recycling: How to Handle the Battery Pack Disassembly Process

ABEE is leading the way in sustainable battery recycling, focusing on the efficient disassembly of electric vehicle (EV) battery packs. Through the integration of robotics and automation, ABEE enhances safety and operational efficiency in the recycling process, while contributing to a circular economy by repurposing or recovering valuable materials for future use in energy solutions.

Smart handling of contact lenses in automated manufacturing

The SMARTHANDLE project focuses on developing advanced handling systems for automated manufacturing processes. The project brings together partners specialising in hardware, software, and specific manufacturing needs to innovate and improve automated handling technologies. The authors of this blog participate in the Menicon use case.

ALUMIL participates in the European Research Project SMARTHANDLE

ALUMIL is pleased to announce its participation as a pilot case in the European Research Project SMARTHANDLE which aims to address the modern challenges of the manufacturing sector in the European Union by enhancing productivity, flexibility, and sustainability in the production process.

SMARTHANDLE - Advancing Human-Centric Robotics for Future Work Environments

Advancements in AI and robotics are reshaping our work environments. Today, robots are integrated into workplaces to support employees, lighten their workload, and increase efficiency. Despite these benefits, the introduction of robots into the workforce can cause disruptions in the way we work.

Revolutionizing Robotic Automation: The Role of Machine Learning in 6D Pose Estimation

In the ever-evolving landscape of robotics and automation, achieving accurate 6D pose estimation has become a fundamental requirement for advancing various handling tasks. From depalletizing to pick-and-place, the ability of robots to accurately understand the spatial orientation and position of objects is essential. However, traditional hard-coded solutions have proven inadequate, often failing in the face of even minor changes in setup, leading to downtime and significant costs associated with constant readjustment.

SMARTHANDLE Architecture: Integrating Innovation for Enhanced Production Efficiency

In recent years, the research community has dedicated significant effort to improving and developing technologies that play a vital role in advancing the next generation industrial robotic applications.

DISASSEMBLY OF EV BATTERIES: A CHALLENGE

SMARTHANDLE will improve environmental aspects targeting the Sustainable Development Goals (SDGs), specifically by activities focused on battery recycling, supporting circular economy and the European Green Deal objectives.

Human perception for collaborative robotic environments in SMARTHANDLE project

Human-robot collaboration (HRC) is a growing topic of interest. Rather than replacing humans, collaboration enables both humans and robots to work together. This eliminates the need for robots to be kept separate from the workforce for safety concerns.

Enhancing AI-Driven Motion Planning in Dual-Arm Robotic Manipulation

The industrial landscape continuously evolves by prioritizing reconfigurability towards addressing the ever-increasing market demands for personalized products. Robotics can emerge as a pivotal enabler through the embodiment of intelligent resources ready to produce new products in a repeatable and efficient manner.

Revolutionizing Industrial Handling Operations: KUKA's Innovations in the SMARTHANDLE Project

Within the project SMARTHANDLE KUKA is working on enhancement of the productivity, flexibility, and sustainability of the handling operations together with research and industrial institutions from Greece, Spain, the Netherlands, Luxemburg, and Belgium.

Grasping the Future: Revolutionizing Industrial Manipulation with SMARTHANDLE's AI-Powered Strategies

In the contemporary industrial landscape, it is imperative to transform current production lines, both manual and automated, into highly efficient and versatile lines. However, pursuing "producing more and diverse with less" underscores the evolution toward this goal. In addition, this pursuit is accompanied by a series of challenges that need to be considered. For instance, the proliferation of product variants challenges the development of reconfigurable and flexible handling tools and strategies, capable of seamlessly accommodating a wide array of product types.

SMARTHANDLE - Advancing Human-Centric Robotics for Future Work Environments

Advancements in AI and robotics are reshaping our work environments. Today, robots are integrated into workplaces to support employees, lighten their workload, and increase efficiency.

Towards Digital Transformation: SMARTHANDLE EU project Industrial pilots

SMARTHANDLE aims to investigate and develop technologies that can effectively support the European industry.

The Role of Roboception's Advanced Machine Learning Approach in SMARTHANDLE

SMARTHANDLE aims to investigate and develop technologies that can effectively support the European industry.

INTERACTIVE PROGRAMMING OF FLEXIBLE ROBOTS

European industry is moving into the future, combining automation, artificial intelligence, Internet of Things (IoT)